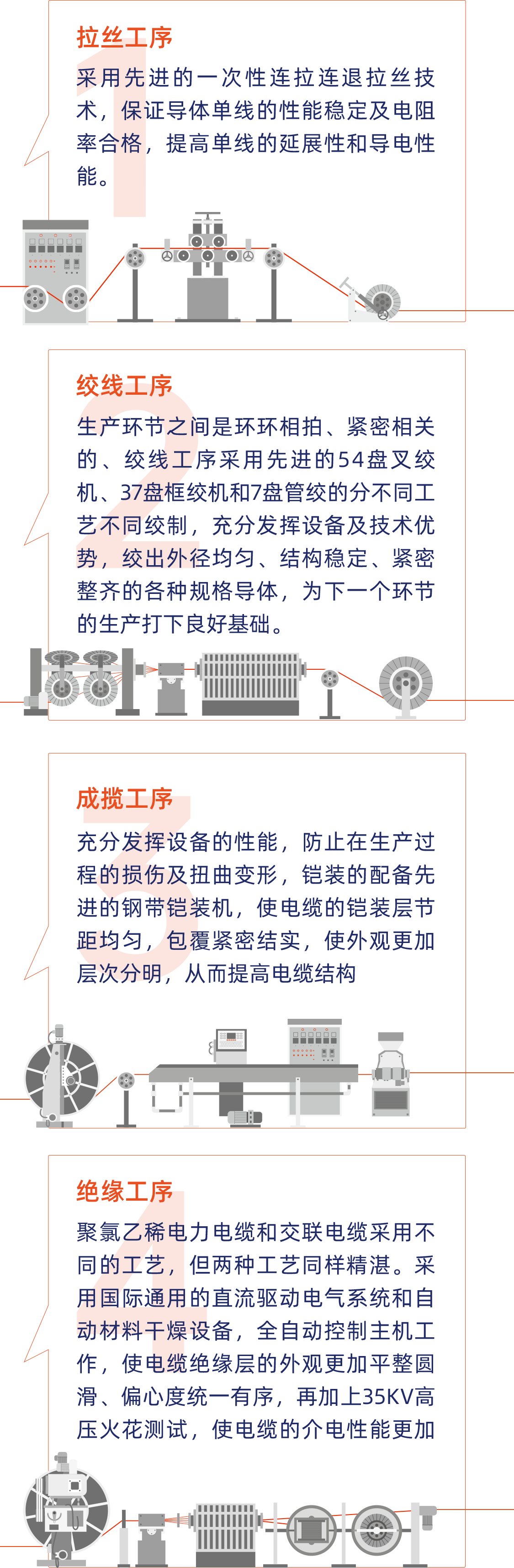

Sunwin cable has international advanced production line and technology leading high-precision production equipment. The introduction of a variety of high-quality winch equipment, to meet the production needs of different specifications. It is equipped with advanced steel tape armoring machine which can improve cable structure performance, international DC drive electric system and automatic material drying equipment. It can make full use of equipment and technical advantages to improve production efficiency.

The whole process of the cable is closed and specialized management. Each process is subject to the design and specification of the engineer's scientific rigor. It is equipped with professional technicians to check and make sure that the production quality of each cable is not in any difference with our standard.

Shengyu Cable has a complete cable R&D system

Sunwin Cable spends a great deal of money to build an industry-leading R & D testing center, has a strong scientific research strength and professional testing team of more than 50...

BSEN 60331-1-2的垂直火焰测试旨在评估单电缆长度下的阻燃性能。这种火焰传播的垂直火焰测试是电缆实验室电缆测试能力的一部分。

有几种测量方法对电缆的构造及其是否符合相关标准至关重要。这些是由我们的专业技术人员进行的一些关键电缆测试,作为我们内部质量保证过程的一部分,但也作为第三方服务提供,以确定是否符合从...

用于确定拉伸强度和伸长率的测量的电缆测试用于确定绝缘和护套化合物的机械性能。 标准BS EN 60811-501确定了应用于交联和热固绝缘和护套材料的电缆测试方法。

导体电阻电缆测试在全长电缆或至少1米长的电缆样品上进行,并根据BS EN 60228测量。该测试确定1类、2类、5类和6类导体的直流电阻,用于普通圆形或异形铜、镀金属铜、铝和铝合金。

气体排放测试,更正式地称为气体测试,是为了满足IEC 60754(以前的BS EN 50267-2)的要求。测试分为两部分:卤酸气体含量的测定和pH测定的酸度测定。

热定型测试是一种直接确定绝缘材料或护套材料是否充分交联的方法。交联材料是一种被改变以加强和增加聚合物链之间的键合的材料。当绝缘材料和外护套材料交联时,通常是为了提高机械和电气性能。

Choose high-precision, high-purity, impurity-free raw materials, pursue the sustainable development of the environment, source saving and regeneration. Let toxic substances be self-contained in our products and production processes. Therefore, we design products with greener, safer materials to reduce and eliminate these toxic substances.

Our production process through the professional engineers for rigorous design and standardization, each link has a scientific control management method, meticulous to each process, each quality control point. The production personnel must pass the strict on-the-job training to produce the work, must wear the uniform in the production process, specialized personnel special operation machinery and equipment.

Each finished product must pass the most precise testing equipment to pass the strict inspection and screening to be able to get out of the storage, must conform to the national law and regulation and the mandatory standard requirement. Through the high-power pressure testing machine, tension testing machine, electric spark testing machine, projector, bridge tester and other advanced national testing equipment, we further ensure the high qualified rate of product quality, and eliminate all the hidden safety risks.

We care about every user's slightest sense of use, develop a variety of cable products based on "peace of mind", take full account of cable usage in complex environments and improve product performance. Shengyu Cable adheres to the development strategy of product innovation, promotes the localization of technology research and development, and improves the ability of local R & D and innovation through continuous investment and optimization of R & D layout. We have established cable scientific research laboratories, testing centers, established long-term cooperative relations with many research institutions and universities throughout the country, engaged professional mentors to guide and cultivate professional and technical personnel, and maintained the core competitive advantage of Shengyu cable products in the market. After constant efforts, R & D The team has made a series of R & D achievements and made breakthrough success in the research and development of aluminum alloy cable.